Cameron Close

Isle of Wight, UK

project overview

Sustainable homes, providing comfort with extremely low running costs

Cameron Close comprises of 16 family houses and 12 sheltered housing apartments, all of which are Passivhaus certified. The attractive and desirable development sits around inviting streets, with all homes having front and back gardens, while the apartments have generous, landscaped kitchen gardens giving plenty of private outdoor space.

All the homes perform extremely well environmentally and are considered excellent value for money by the local authority, considering the high level of specification, low running costs and long-term environmental benefits.

I haven’t used the heating at all. I don’t like a lot of heating anyway but the temperature’s been fine! I haven’t even thought about putting it on.”

Cameron Close Resident

2017

project journey

Highly specified homes that don’t lose sight of the architect’s vision

Cameron Close sits in the rural village of Freshwater on the Isle of Wight. The site was previously occupied by a Southern Housing Group sheltered housing scheme which was at the end of its life. All the existing homes on the site needed demolishing and we needed to provide homes which were low on energy consumption yet comfortable and healthy for people to live in.

Southern Housing Group did not originally intend for the scheme to be Passivhaus accredited. Yet the group wanted to consider how to respond to the net zero carbon agenda and looked at a fabric-first approach, over the use of micro-renewable technologies. This would enable the scheme to meet the stringent requirements needed to be eligible for grant funding from the Isle of Wight Council, under its Sustainable Community Strategy.

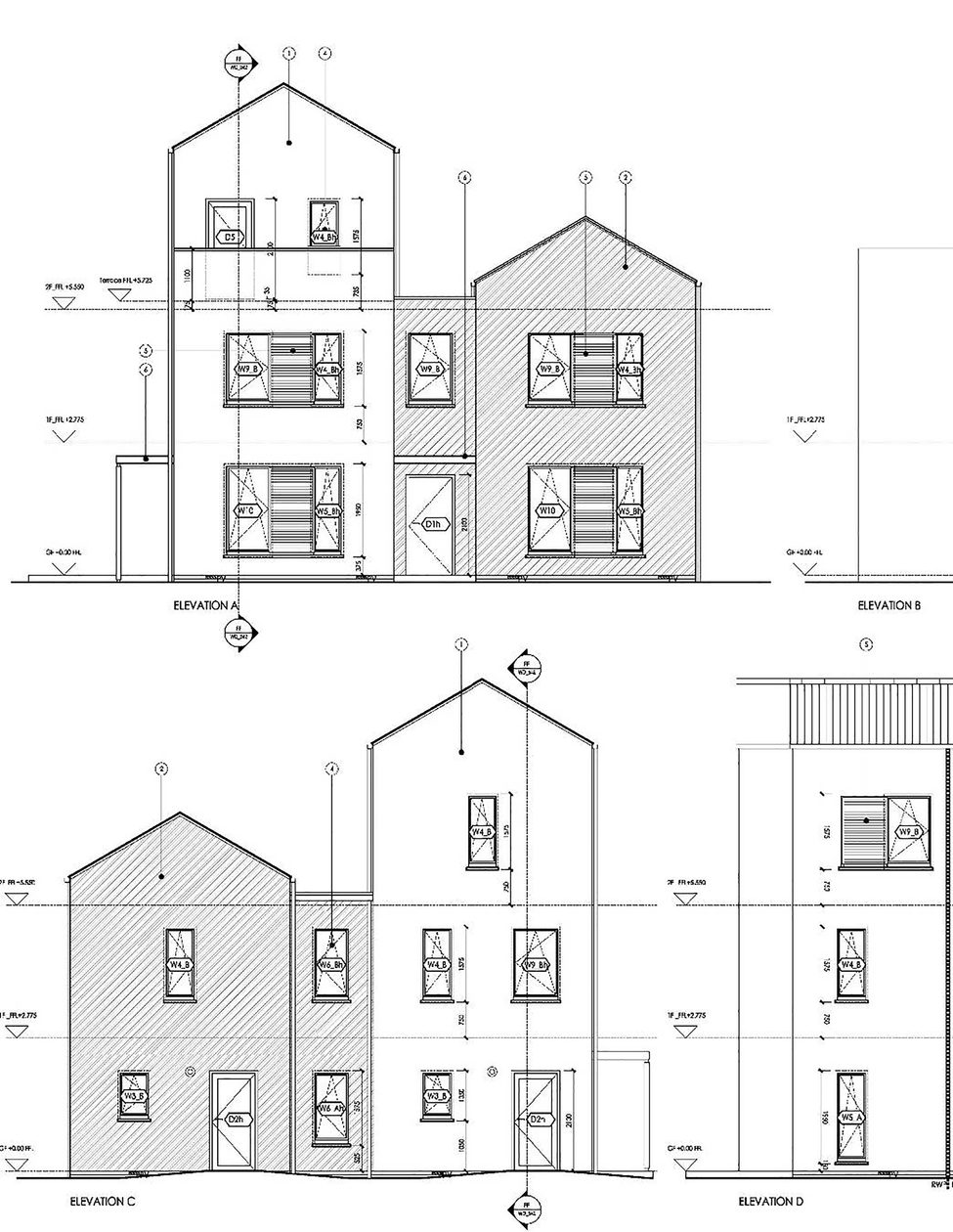

After the decision to go forward with the Passivhaus standard was made, we needed to alter our original stepped and staggered design. In the Passivhaus design, there is a limited number of external walls which you can use, so we needed to reduce these in order to minimise heat loss externally.

By amending the design, we developed a new semi-detached house typology for this project which strays from the typical Passivhaus design. The result is a Passivhaus-compliant community, that doesn’t compromise on quality, comfort or architectural vision.

I love it here. I love the fact it’s so quiet. And it’s warm without having the heating on.”

Cameron Close Resident

2017passivhaus design

Creating desirable homes whilst improving efficiency

challenges and solutions

Innovative design to achieve Passivhaus accreditation

We worked with Passivhaus Consultants, Low Energy Building Consultants (WARM) to ensure that the scheme would meet all the requirements of Passivhaus accreditation. Achieving Passivhaus accreditation required an exacting and meticulous approach but using a solid aircrete frame constructed from the Thin-Joint system meant at least the construction process itself was simplified.

A lot of housing associations have built residential schemes to Passivhaus principles, but have not gone down the full route of Passivhaus certification for all homes. We achieved accreditation by ensuring that everyone in our team, the contractor, the manufacturer and the client were all on board with all the procedures from the start and by taking great care with processes and materials. It was critical to the success of the project that everyone needed to embrace and understand the concept as attention to detail is paramount from the outset.

From a design point of view, Passivhaus is challenging, features such as porches and letterboxes require innovative solutions to provide the same function.

By creating a significant amount of construction drawings and details on-site, we avoided any cold bridging and created extremely airtight homes. We maintained a great relationship throughout delivery with the contractor, which ensured that the execution of our designs was meticulous.

We made sure everyone bought into it at every level so everyone could understand the consequences of their actions.

Everything had to be done by the book – around every window, every door and every pipe. A key lesson for us was the need for forward planning, especially in mechanical and electrical services. You can’t have plumbers just drilling through a wall. Design details have to be thought through at the front end much more than usual.”

David Harris

Financial Director, Stoneham Construction

passivhaus design

Offsetting the Passivhaus over the scheme’s lifecycle

The extra capital cost incurred by designing homes to achieve Passivhaus accreditation had the potential to be offset by lower running costs. This uplift included enhanced triple glazing, more insulation, heavier gauge membranes and additional care during construction to achieve the required airtightness. By minimising fuel poverty and providing homes with lower running costs, the residents of Cameron Close are happier and in their homes for longer, reducing voids for Southern Housing Group.

£900

per year

estimated energy bill savings

£25k

cost saving

estimated for the entire scheme

11

years payback

period estimated for the capital cost

20%

faster

construction methods

100%

affordable

homes

84%

lower than average

gas consumption in 2015

PASSIVHAUS DESIGN

An exacting, meticulous and fabric-first approach to construction

key information

Project summary

Location

Newport, Isle of Wight, PO30 5BF

Client

Southern Housing Group

Completion

2015

Value

£4.2m

Size

0.636 ha

Environmental

Passivhaus accredited

U values

Ground Floor - 0.1W/m2K

Roof - 0.8W/m2K

Ext. wall (houses) - 0.8W/m2K

Ext. wall (apartments) - 0.11W/m2K

Windows - 0.96W/m2K

Includes

16 family houses

12 sheltered housing apartments

Awards

Housing Design Awards 2016

Shortlisted

Housing Innovation Awards 2017

Shortlisted - Most Innovative Affordable Housing Scheme

Contact

Interested in

learning more?

Learn more about 'Cameron Close' and other projects by reaching out to one of our team

Get in touchRelated Projects

The Pheasantry

This highly environmentally conscious development, consists of 26, 100% affordable family homes, all of which meet the Passivhaus standard.

Acton Gardens

Part of the significant regeneration plan of South Acton Estate, bringing a collection of local neighbourhoods that encourage connectivity between residents.

Radbrook Village

Our four-phased masterplan, is an impressive development of 126 new and refurbished homes, designed to nurture the diverse community it is set in.